Digital Transformation: A Rapid Evolution

The COVID-19 crisis disrupted our social, economic, business, and healthy living. The unprecedented crisis made us rethink some of our industrial and supply chain practices. It also spurred us along paths more quickly than expected. One of these paths was the digital transformation of our workplaces.

Rapid technology evolution—increases in ‘Industry 4.0’ pressures, and changing supply chain and customer expectations—have each resulted in greater pressures for digital transformation. This digital transformation sped up with COVID-19 disruptions.

As a research group, it provided us with unprecedented opportunities to examine this evolution. We investigated regional and national supply chains. We found that before the COVID pandemic, many organizations, including small and medium-sized manufacturing enterprises (SMEs), were struggling to maintain competitiveness with the rapid technological advancements.

The pandemic further amplified the challenges SMEs faced before the COVID-19 outbreak. The disruptions to traditional business models and supply chain networks were especially detrimental to SMEs. Let us jump to the punchline—SMEs that prioritized digital transformation were better able to weather the multitude of disruptions and were more competitively robust in the aftermath of the major throes of COVID-19.

The digital transformations included accelerated trends toward remote workforces. This work-from-home (WFH) transformation made it imperative for companies to adapt to this new normal—with adaptation still occurring. Buyer—supplier relationships could be dealt with virtually—changing the collaborative nature of cooperation.

The benefits of digital transformation of manufacturing companies are manifold. Digital transformation can support operationally informed decisions, optimize operations, and strategically drive business success.

Digital tools and resources include data analytics, automation, cloud computing, artificial intelligence, and machine learning. Each can provide valuable insights, help identify patterns and trends, streamline processes, reduce errors, and—overall provide businesses with a competitive edge.

Digital Transformation Maturity

Regardless of where an organization and its supply chain fall on tools, initiatives, and processes, it is imperative to adapt its existing information technology (IT) infrastructure to be digitally ready.

Many companies, especially SMEs with limited resources, are apprehensive about investing in the wrong digital choices—although cost remains a major concern for businesses of all sizes. SMEs typically have less resilience and flexibility to deal with financial uncertainties during times of crises and uncertainty. The OECD has found that SMEs have relatively lower levels of digitization and face challenges in accessing and adopting new technologies.

Supply chains cannot function without SMEs. In order to establish a resilient, flexible, and agile production system and develop supply chain capacity, it is essential for businesses and SMEs to improve their technological capabilities.

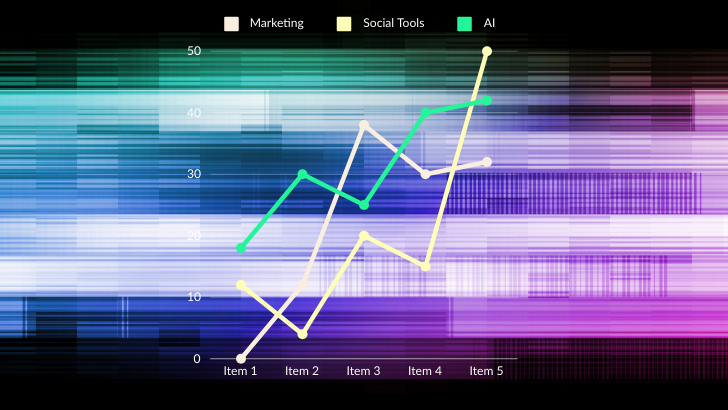

Our research and preliminary findings indicate that the level of digital maturity, particularly among SMEs, is an important consideration across several industries. But, it is not always clear how well SMEs are doing (Figure 1). The lack of suitable SME-specific solutions and understanding of their digital transformation maturity is a major obstacle.

Figure 1: Assessment scale applied for digital maturity level evaluation

To address this issue, we have developed a free online assessment tool that can determine the digital maturity level of any company based on five key dimensions: governance, culture, technology, customer, and operations.

The basic outcome of the assessment tool is a range of where an SME is on a series of digital transformation best practices. There are various outcomes from a ‘digital starter’ to a ‘digital leader’ (see Figure 2).

Figure 2: The digital maturity outcomes of an assessment tool for SME digital transformation.

Figure 2: The digital maturity outcomes of an assessment tool for SME digital transformation.

Once a company completes the assessment, they will receive a free report outlining their current digital maturity level, strengths, and weaknesses. The report will also offer a range of activities and strategies for each dimension, including suitable training programs provided by educational organizations such as MassMEP or AimNet; two non-profit organizations supporting manufacturing development in Massachusetts.

Time is of the essence for SMEs, and they must embrace digital technologies to innovate, compete, and remain resilient in the face of ongoing disruptions. While COVID-19 may not be the last global health crisis—or disruption—businesses can prepare themselves for future challenges by assessing risks and technological readiness and developing mitigation plans and actions.

To evaluate your company’s technological readiness, please click here for instructions on how to use our free assessment tool. Give it a test run!

Let us know your opinion.